S45C

Ocel středního uhlíku

Aplikace vyžadující pevnost a odolnost proti nárazu součásti, kvůli svému vysokému obsahu uhlíku, proto má vyšší pevnost v tahu, tažnost a odolnost proti opotřebení, ale není vhodná pro svařování nebo tváření.

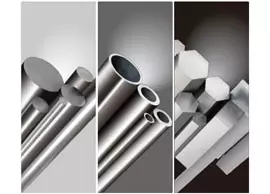

Tento ocelový stupeň lze dodávat ve mnoha standardních tvarech, včetně kulatých, čtvercových, šestihranných a desek. Obecně se používá v matkách a šroubech, osách, válečcích, pružinách, drátech, rámových kolech, tyčích, dílech motoru, razících nástrojích, kladivech, podložkách s pojistkou / pojistných kolíčkách, turbínových rotorů, železničních kolejnicích, válcových pouzdrech, ručních nástrojích, šroubech, železničních kolech, převodovkách, zahradních nůžkách atd.

Středně uhlíková, středně pevná ocel dodávaná jako kovaná nebo normalizovaná

Účel

S45C se široce používá v mechanických součástech a konstrukční oceli.

Mezinárodní srovnání materiálů

|

EU EN | POHŘBÍT ISO |

USA AISI |

JAPONSKO JIS |

NĚMECKO DIN |

ČÍNA VB |

FRANCIE AFNOR |

ITALIE UNI |

|---|---|---|---|---|---|---|---|

|

C45E C45 | C45 | 1045 | S45C |

CK45 C45 Cf45 | 45 |

XC45 XC48H1 AF65C45 C45 |

C45 1C45 C45 |

|

ŠPANĚLSKO UNE |

Švédsko SS |

Finsko SFS |

Polsko PN |

Česko CSN |

Rakousko ONORM |

Rusko GOST |

Anglie BS |

|---|---|---|---|---|---|---|---|

| C45K |

1672 1650 | C45 | 45 | 12050 | C45SW | 45 | 080M46 |

**Tato srovnávací tabulka slouží pouze k orientaci. Normy a stupně různých zemí mají mírně odlišné chemické složení. Podrobnosti naleznete v databázi.**

Chemické složení (JIS G4051)

| C(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) | Ni(%) | Cu(%) |

|---|---|---|---|---|---|---|---|

| 0.42-0.48 | 0.15-0.35 | 0.6-0.9 | 0≦0.03 | 0≦0.035 | 0≦0.2 | 0≦0.2 | 0≦0.3 |

Podmínky tepelného zpracování

- Zakalení: 880℃ Chlazení v peci

- Normalizace: 880~870℃ Chlazení na vzduchu

- Kalení: 820~870℃ Chlazení ve vodě

- Popouštění: 550~650℃ Rychlé chlazení

Mechanické vlastnosti

(1) Materiál

Tlaková pevnost (kgf/mm²): ≧58

Mez pevnosti (kgf/mm²): ≧35

Prodloužení (%): ≧20

Snížení průřezu (%): ≧45

Tvrdost (Hb): 167~229

(2) Po tepelném zpracování

Tahová pevnost (kgf/mm²): ≧70

Mez pevnosti (kgf/mm²): ≧50

Prodloužení (%): ≧17

Snížení průřezu (%): ≧45

Tvrdost (Hb): 201~269

Rozsah velikostí

| Tvar | Velikost (mm) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Kolo Bar | 13 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 |

| 26 | 27 | 28 | 30 | 32 | 34 | 36 | 38 | 40 | 42 | 44 | 45 | |

| 46 | 48 | 50 | 53 | 55 | 57 | 60 | 62 | 65 | 67 | 70 | 72 | |

| 75 | 78 | 80 | 82 | 85 | 90 | 92 | 95 | 100 | 103 | 105 | 110 | |

| 115 | 120 | 125 | 130 | 135 | 140 | 145 | 150 | 155 | 160 | 165 | 170 | |

| 175 | 180 | 185 | 190 | 200 | 210 | 220 | 230 | 240 | 250 | 260 | 270 | |

| 280 | 290 | 295 | 305 | 315 | 325 | 335 | 345 | 355 | 365 | 375 | 385 | |

| 395 | 405 | 415 | 425 | 435 | 445 | 455 | 465 | 475 | 485 | 495 | 505 | |

| 515 | 525 | 535 | 545 | 555 | 565 | 575 | 585 | 595 | 605 | |||

- Aplikace oceli

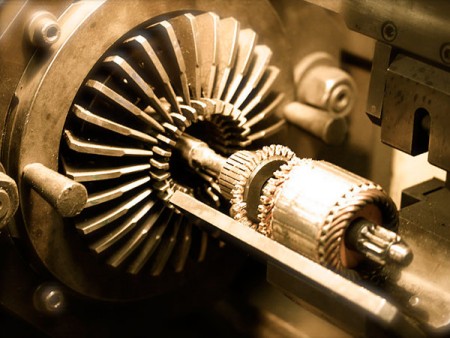

Převodovka

Existuje mnoho typů převodovek, například: přímé převodovky, ozubená kola, časovací kladky, šroubové převodovky, vnitřní převodovky, lišty, kuželová ozubená kola, zakřivená kuželová ozubená kola, kuželová ozubená kola se sklonem nula stupňů, posunuté šroubové převodovky, šnekové převodovky, Halberdova převodovka. Materiál ozubeného kola musí mít silnou ohybovou únavovou pevnost a pevnost při kontaktu, a povrch zubu musí mít dostatečnou tvrdost a odolnost proti opotřebení, a jádro musí mít určitou pevnost a houževnatost. Materiály, které doporučujeme pro použití v převodovkách, jsou následující.

Vřeteno obráběcího stroje

V jednom stroji může být několik vřeten. Existuje mnoho typů vřeten, včetně brusných vřeten, elektrických vřeten, vřeten s nízkou rychlostí, vřeten s vysokou rychlostí, vřeten pro gravírovací stroje, vřeten pro frézky, vřeten pro soustruhy atd. Proto by mělo být vřeteno vyrobeno z materiálů s nejvyšší stabilitou, tuhostí a účinností. Materiály, které doporučujeme pro použití vřetena obráběcího stroje, jsou následující.

Hřídele pohonu

Pro umožnění změn v zarovnání a vzdálenosti mezi hnacími a poháněnými komponentami obsahuje hnací hřídel jeden nebo více kardanových kloubů a spojek. Jejich materiály musí proto odolávat silnému tlaku a zároveň se vyhnout nadměrnému přídavnému váhu, který by zvýšil zpětnou setrvačnost. Materiály hřídele pohonu, které doporučujeme, jsou následující. Materiály pro aplikaci hřídele pohonu, které doporučujeme, jsou následující.

Řezné nástroje

Existuje mnoho typů řezných nástrojů, například: frézy, vrtáky, kotoučové pilové čepele, vyvrtávačky, řezné nástroje z PCD (polykrystalický diamant), děrovací nástroje, soustružnické nástroje, razidla atd. Kvalita materiálu řezného nástroje ovlivní kvalitu povrchu, účinnost řezání, životnost nástroje a další faktory. Proto by měl být vybraný materiál nástroje vysoce tvrdý, odolný proti opotřebení, pevný, houževnatý a odolný vůči teplu. Materiály, které doporučujeme pro aplikaci řezných nástrojů, jsou následující.

Díly stroje

Materiálové typy mechanických částí zahrnují kovové materiály, nekovové materiály a kompozitní materiály. Kovové materiály se dělí na železné a neželezné kovové materiály. Železné kovové materiály zahrnují ocel, litinové oceli a litiny, které mají dobré mechanické vlastnosti (jako je pevnost, tažnost, houževnatost atd.) a jsou relativně levné a snadno dostupné. Neželezné kovové materiály mají výhody nízké hustoty, dobré tepelné a elektrické vodivosti. Materiály pro aplikaci obrábění dílů, které doporučujeme, jsou následující.