OEM Service

Precision OEM Service

In response to raising demand for high efficiency, JFS provides a complete range of CNC services for our customers around the world. We are happy to offer machining services to any of our customers when they buy any of our steel products. By sizing the materials to the exact specifications given by our customers (as semi-finished or finished products) JFS is able to reduce processing time and cost. We provide a wide variety of additional services, like steel cutting, steel drilling, heat treatment, machining services, as well as a flexible approach to meet customers’ needs.

To know more about our additional services, please visit the pages below.

Steel Cutting

Ju Feng has more than ten sets of circular saw machines and band saw machines, which can cut a large variety of steel materials (such as carbon steel, high carbon steel, alloy steel, tool steel, seamless steel tubes, free cutting steel, stainless steel, square bars, hexagonal bars, special shaped steel, steel plate, etc.).Using fully actualized equipment, JF has the ability to cut steel with a maximum outer diameter of 600mm and a length tolerance within 0~1mm. By sizing the material to the customer need, our company is able to reduce processing time for customers and reducing not only the overall scrap costs but also the delivery costs.

Steel Drilling

In recent years, Ju Feng has acquired several sets of high-speed metal drilling machines (including trepanning drilling, center drilling, and fast drilling…etc.) to meet customer’s needs. With computerized automation, the ability to drill the hole with the diameter from 13 to 250mm and a depth between 0 and 490mm capacity. The steel drilling services we provide to our customers, can help them to reduce a lot of the production time. In addition to meeting all customer specifications, it can also help customers achieve substantial cost benefits.

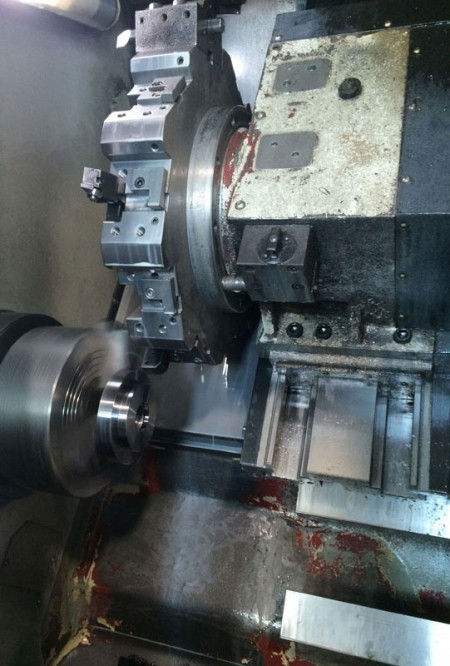

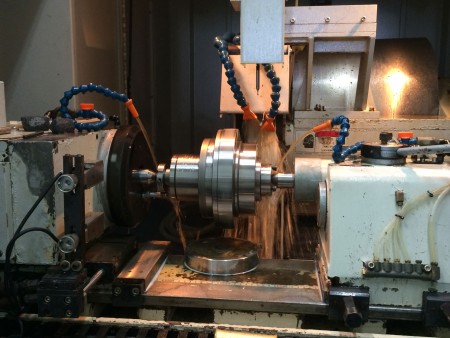

CNC Turning Service

Ju Feng´s engineering team uses precision lathe equipment, which enable them to meet the CNC machining needs of customers. From simple drilling to complex design turning technology, we can produce all kinds of parts for customers.Ju Feng is located in Taichung, Taiwan, with more than 30 years of professional machining experience, constantly providing high-quality precision machining services for export, including CNC turning services. Ju Feng's team is one of the leading companies in the industry, providing high-efficiency and high-precision turning services, using high-end CNC equipment, engineering and the experience to achieve highly complex manufacturing processes to meet customers' demands.

CNC Milling Service

Ju Feng's has advanced CNC Milling machines, Mill-Turn Multitasking Machines, and Auto Loaders, enable us to have higher performance in production, higher efficiency, higher quality and higher precision of finished parts. Our milling equipment can process workpieces with lengths up to 1300mm, 600mm width, and with heights of 650mm. Ju Feng's team is able to provide services from simple drilling to precision milling of difficult design, successfully meeting customers' demands.

CNC Grinding Service

Located in Taichung, Taiwan, and with more than 30 years of experience in the steel sector, Ju Feng Grinding Center has advanced technology equipment, highly-skilled machinists and a temperature-controlled environment, which enables JFS not only grinding customized specifications, but also providing OEM services to meet customers' demand.. Ju Feng's engineering team uses computer numerically controlled grinding machines and dual-spindles grinders to provide high-volume precision grinding service. Ju Feng is an OEM service provider and also offer the services in precision inner dia. grinding, outer dia. grinding, and surface grinding with high tolerance and reliable quality.

Heat Treatment

Heat treatment is one of the most important procedures in the manufacturing process of mechanical parts and molds. The heat treatment services that Ju Feng can provide include: vacuum heat treating, metal hardening, nitriding, metal quenching, metal tempering, normalizing, annealing, martempering, austempering, and cryogenic hardening, etc.By heating the steel to a proper temperature range, maintaining it for a proper time, and then cooling it at a proper speed, improve the properties of the steel materials (such as wear resistance, corrosion resistance, etc.), it can also enhance the microstructure and the pressure resistance of steel material.For example, white cast iron can improve its plasticity after a long-time annealing treatment; if the gear goes through the correct heat treatment process, its service life can be longer than that of a gear without heat treatment; in addition, almost all molds need heat treatment before they can be used. Generally, the steel products that are often heat-treated include gears, shafts, sleeves, motor shafts. Ju Feng has extensive expertise in the heat treatment of the following materials and special alloys: carbon steels, free cutting steels, low carbon alloy steels, structural steels, tool steels, bearing steels, spring steels, cast steels, etc.

Machining Services

In order to speed up the customer's CNC machining service process and reduce the cost of parts production, Ju Feng company cooperates with alliance business partners to provide customers with semi-finished products processing services for precision parts. Our machining service provides value-added to a full range of steel grade solutions, from steel material to semi-finished or finished components. Our workshop machining services include CNC lathing, milling, grinding, drilling, high speed machining, surface treatment and so on.