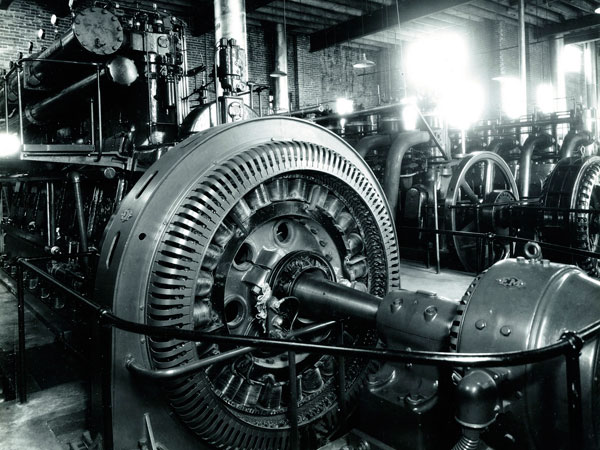

Drive Shafts

Drive shaft which is also known as propeller shaft (prop shaft), or Cardan shaft is a mechanical component for transmitting torque and rotation.

In order to allow changes in the alignment and distance between the driving and driven components, the drive shaft contains one or more universal joints and couplings. Therefore, their materials must withstand strong pressure, while avoiding excessive additional weight to increase reverse inertia.

The materials of drive shaft we recommend are as below.

The materials for drive shaft application that we recommend are as below.

- Related List

SNCM439

Alloy Steel

Equivalent Grades: GB 40CrNiMoA, 45CrNiMoVA, JIS SNCM439, and ASTM 4340, 9840. SNCM439 is a kind of refining steel and has the properties of high hardness and toughness. It is often used for the manufacture of screws, gears, shafts, nuts, pistons, the automobile parts required high toughness and so on.

SNCM420

Alloy Steel

Equivalent Grades: JIS SNCM420 and ASTM 4320. SNCM420 is mainly used for railway bearings, drive shafts, gears, screws, cutting tools and other products which need impact resistance and wear resistance. SNCM420 is a kind of alloy carburizing steel as SNCM220. The mechanical properties between SNCM420 and SNCM220 are almost the same. The surface of SNCM420 is high hardness and has good performance in abrasion resistance and contact fatigue strength. Its core which has high toughness can withstand high impaction. There are two differences between SNCM420 and SNCM220 which are the standard and the amount of Ni content. The Ni content of SNCM420 is more than the one of SNCM220.

SNCM220

Alloy Steel

Equivalent Grades: GB 20CrNiMo, JIS SNCM220, ASTM 8615, 8617, 8620, 8622, DIN 20MoCr4. SNCM220 is mainly used for automobile bearings, drive shafts, gears, screws, cutting tools and other products which need impact resistance and wear resistant. SNCM220 is a common type of alloy carburizing steel or bearing steel with the surface of high hardness, abrasion resistance and contact fatigue strength. Its core which has high toughness can withstand high impaction.

SCM440

Alloy Steel

SCM440 is medium carbon chromium molybdenum alloy steel, which is an alloy steel containing chromium and molybdenum. It has the advantages of stable composition, low harmful elements, high steel purity, small decarburization layer and few surface defects. It is easy to be spheroidized and has low cold cracking rate. It is usually hardened and tempered. The ultimate tensile strength is 850-1000 Mpa. This material achieves a very good balance between strength, toughness and wear resistance. The chromium content of the alloy provides good hardness permeability, and the molybdenum element imparts average hardness and high strength.SCM440 reacts well in heat treatment and it is easy to process under heat treatment conditions. This material provides many desirable properties such as good strength and wear resistance, excellent toughness, good ductility and resistance to high-temperature stresses.

SKD61

Tool Steel

Equivalent Grades: GB 4Cr5MoSiV1, JIS SKD61, ASTM H13, DIN X40CrMoV5-1. SKD61 is the tool steel, mold steel, and middle carbon steel possessing high hardness and wear resistance after heat treatment. It also has the good performance of hardenability and thermal fatigue stability. SKD61 not only supports huge mechanical stress, but also thermal stress during working repeatedly. It is widely used to produce the cutting tools (drilling cutter, circular cutter, scissor, etc.), cold/heat work dies and measuring implements and further to manufacture the pistons, valves, valve seats of fuel pump of diesel engine, and ejector sleeves, punching machine, and other tools which work in high temperature condition.

SKD11

Tool Steel

Equivalent Grades: GB Cr12MoV, JIS SKD11, AISI/SAE D3, DIN 2X165CrMoV12. SKD11 is the tool steel, die steel, and high carbon steel possessing high hardness, strength and wear resistance. Its surface is grinded precisely. It is often used for the stamping dies, plastic molds, and so on.

SCM420

Alloy Steel

Equivalent Grades: GB 20CrMo, JIS SCM420, ASTM 4118, DIN 25CrMo4. SCM420 are alloy steel with high hardenability, temper brittleness, well weldability, less cold cracking tendency, good machinability, and great cold plastic strain. SCM420 generally are used for the parts which need high wear resistance, such as gears, shafts, high-pressure pipes, all kinds of fasteners, and so on.

SCM415

Alloy Steel

Equivalent Grades: GB 15CrMo, JIS SCM415, DIN 15CrMo5. SCM415 whose surface are processed through carburizing hardening treatment are used for the parts which need high toughness or wear resistance, such as cylinder piston, crankshaft, gears, pin, shafts and so on.