SNCM439

Alloy Steel

Equivalent Grades: GB 40CrNiMoA, 45CrNiMoVA, JIS SNCM439, and ASTM 4340, 9840. SNCM439 is a kind of refining steel and has the properties of high hardness and toughness. It is often used for the manufacture of screws, gears, shafts, nuts, pistons, the automobile parts required high toughness and so on.

A low alloy steel containing nickel, chromium and molybdenum

Purpose

SNCM439 is widely used in high toughness alloy structural steel.

International Comparison of Materials

| EU EN | INTER ISO | USA AISI | JAPAN JIS | GERMANY DIN | CHINA GB | FRANCE AFNOR | ENGLAND BS |

|---|---|---|---|---|---|---|---|

| -- | -- | 4340 9840 | SNCM439 | -- | 40CrNiMoA 45CrNiMoVA | -- | -- |

| ITALY UNI | SPAIN UNE | SWEDEN SS | POLAND PN | FINLAND SFS | AUSTRIA ONORM | RUSSIA GOST | NORWAY NS |

|---|---|---|---|---|---|---|---|

| -- | -- | -- | -- | -- | -- | -- | -- |

**This comparison table is for reference only. The standards and grades of various countries have slightly different chemical compositions. Please refer to the database for details.**

Chemical Composition(JIS G4051)

| C(%) | Si(%) | Mn(%) | P(%) | S(%) | Ni(%) | Cr(%) | Mo(%) | Cu(%) |

|---|---|---|---|---|---|---|---|---|

| 0.36-0.43 | 0.15-0.35 | 0.6-0.9 | 0≦0.03 | 0≦0.03 | 1.6-2.0 | 0.6-1.0 | 0.15-0.30 | 0≦0.3 |

Conditions of heat treatment

- Annealing: 820℃ Hot Annealing, 670℃ Cold Annealing

- Normalization: 820~870℃ Air Cooling

- Hardening: 820~870℃ Oil Cooling

- Tempering: 580~680℃ Water Cooling

Criterion for heat treating conditions revise:

- Ac: 730~775℃

- Ar: 710~655℃

- Ms: 285℃

Mechanical properties

Tensile strength (kgf/mm²): ≧100

Yield strength (kgf/mm²): ≧90

Elongation (%): ≧16

Cross section reduction rate (%): ≧45

Impact value (J/cm2): ≧7

Hardness (Hb) : 293~352

Size Range

| Shape | Size(mm) | ||

|---|---|---|---|

| Round Bar | 16, 19, 22, 25, 28, 30, 32, 34, 36, 38, 40, 42, 44, 46, 48, 50, 55, 60, 65, 70, 75, 80, 85, 90, 95, 100, 110, 120, 130, 140, 150, 160, 170, 180, 190, 200, 210, 220, 230, 240, 250. | ||

- Steel Application

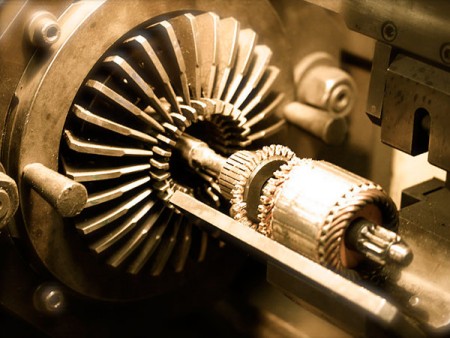

Gear

There are many types of gears, such as: spur gears, sprocket gears, timing pulleys, helical gears, internal gears, racks, spur bevel gears, curved bevel gears, zero-degree bevel gears, staggered spiral gears, worm gears, Halberd gear. The material of the gear must have strong bending fatigue strength and contact fatigue strength, and the tooth surface must have sufficient hardness and wear resistance, and the core must have a certain strength and toughness.The materials for gear application that we recommend are as below.

Machine Tool Spindle

There may be several spindles in a machine. There are many types of spindles, including grinding spindles, electric spindles, low-speed spindles, high-speed spindles, engraving machine spindles, milling machine spindles, lathe spindles, etc. Therefore, the spindle should be made of materials with the highest stability, rigidity and efficiency.The materials for machine tool spindle application that we recommend are as below.

Drive Shafts

In order to allow changes in the alignment and distance between the driving and driven components, the drive shaft contains one or more universal joints and couplings. Therefore, their materials must withstand strong pressure, while avoiding excessive additional weight to increase reverse inertia. The materials of drive shaft we recommend are as below.The materials for drive shaft application that we recommend are as below.

Bearing Shaft

There must be a shaft in the motor, which is mainly used to drive the motor and generate kinetic energy for other devices.The materials for bearing shaft application that we recommend are as below.

Cutting Tools

There are many types of cutting tools, such as: milling cutters, drills, circular saw blades, reamers, PCD (Polycrystalline Diamond) cutting tools, hole drills, lathe tools, stamping tools, etc. The quality of the cutting tool material will affect the surface quality, cutting efficiency, tool life and other factors. Therefore, the selected tool material should have a high degree of hardness, wear resistance, strength, toughness and heat resistance.The materials for cutting tools application that we recommend are as below.

Worm Shafts

When the worm wheel is running, it will generate a lot of heat energy due to contact friction. When the contact surface pressure is too high, coupled with high temperature, it is easy to cause wear on the tooth surface. Therefore, the worm rod should be made of wear-resistant and rigid materials.The materials for worm shaft application that we recommend are as below.

Machine Parts

The material types of mechanical parts include metallic materials, non-metallic materials and composite materials. Metal materials are divided into ferrous metal materials and non-ferrous metal materials. Ferrous metal materials include steel, cast steels and cast irons, which have good mechanical properties (such as strength, ductility, toughness, etc.), and are relatively cheap and easy to obtain. Non-ferrous metal materials have the advantages of low density, good thermal and electrical conductivity.The materials for machining parts application that we recommend are as below.